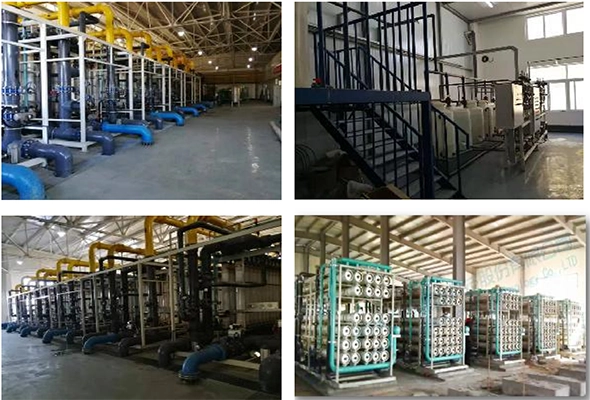

Projects

Wastewater Reuse for chemical park

The comprehensive wastewater generated from a chemical park undergoes treatment using a combination of ultrafiltration and reverse osmosis technologies. With a daily treatment capacity of 10,000 cubic meters, this process achieves an impressive reuse rate of 67%. By effectively removing impurities and contaminants, the treated water can be reused for various purposes, contributing to sustainable water management in the chemical park. This approach not only minimizes the environmental impact of wastewater discharge but also ensures the efficient utilization of water resources, promoting the overall sustainability of the chemical industry.

Process: Ultrafiltration+Reverse Osmosis

Pharmaceutical waste water ZLD

The pharmaceutical wastewater zero liquid discharge (ZLD) system employs a combination of biochemistry, membrane concentration, and evaporation techniques. This process ensures that the output water meets the design requirements with a purity level of at least 95%. Additionally, the desalination rate exceeds 96%, effectively removing salts and impurities. The system guarantees both the desired quantity and quality of the output water, meeting the specified standards. The pharmaceutical industry can achieve sustainable water management while maintaining high levels of purity and minimizing environmental impact.

Process: Biochemistry+membrane concentration+evaporation

Production water for iron ore use

The utilization of seawater for iron ore production involves a daily intake of 20,000 cubic meters, requiring 26 sets of 40ft containers for the process. With the implementation of ultrafiltration (UF) membrane technology, the recovery rate exceeds 90%, ensuring efficient water usage. Additionally, the reverse osmosis (RO) membrane achieves a recovery rate of over 40%. This innovative approach not only enables sustainable water management but also enhances the economic benefits of enterprises. By maximizing water recovery and minimizing waste, the process adds value to the products and contributes to the overall profitability and sustainability of the operation.

Process: Multimedia filter+UF+RO

High salinity wastewater zero liquid discharge (ZLD)

The high salinity wastewater zero liquid discharge (ZLD) system utilizes comprehensive wastewater as the water source and has a daily treatment capacity of 2500 cubic meters. The treatment process involves coagulation sedimentation, advanced oxidation, pretreatment, several-stage membrane concentration, and evaporation. This approach achieves a high desalination rate of over 97% and a recovery rate exceeding 97% for the entire system. The concentrated water volume is effectively managed, ensuring sustainable water usage. The system features a new concentrated water treatment approach that achieves comprehensive wastewater ZLD.